Dynamics in the manufacture of reclosable beverage cartons

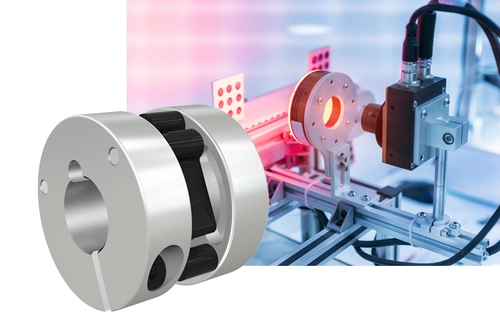

Beverage cartons often have so-called flat closures on the top. Liquids can be poured out without dripping. The carton can be easily reclosed and safely stored to protect it from foreign odours. The flat closures are applied to beverage cartons at extremely high output rates. In line with the dynamic process, lightweight aluminium Semiflex Dynamic couplings are used in closure application drives. Along with its compact design, it fulfils the low rotational inertia requirement.

Precise lifting and pivoting movement in the sealing process

The packaging of filled, ready-for-sale beverage cartons is often sealed by means of systems based on a combined linear and rotary movement.

To do so, the closures are positioned exactly on top of each packaging unit and then carefully screwed onto the locking thread with a defined torque. The main focus of this process is combining the precise linear movement required to exactly position the closure on the thread, with the rotary motion needed for an accurate movement sequence in terms of rotation angle and torque. Articulated coupling Loewe GK is specifically intended for this combined lifting and pivoting movement due to its high axial as well as torsional rigidity. Due to the properties mentioned, it promotes accurate sealing processes.

High output with fold wrapping machines

Compact, automatic fold wrapping machines are often used in the confectionery industry and pack small chocolate bars and similar articles with high output in corresponding wrapping materials. The Semiflex in clamping hub design is used in such compact machines. Due to its high torsional stiffness and precision, it supports the high productivity requirements when wrapping sweets inside and outside.