The handling technology includes comprehensive process steps in order to optimize a wide variety of production processes. They include handling technology, automation and the whole automation and robotics fields. Due to the highest demands in terms of productivity and output rate, the systems work highly dynamically, leveraging the latest servo technology. SCHMIDT-KUPPLUNG provides a broad array of compensating couplings for this - featuring precision and overly low rotational inertia.

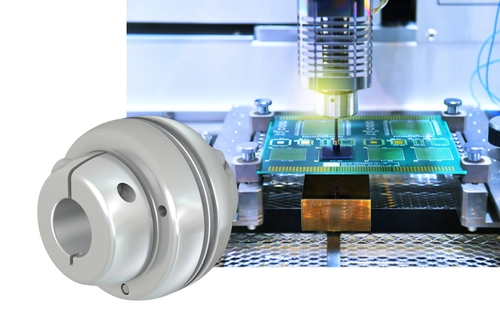

PCB exposure and placement systems

Assembly through precise pivoting/lifting processes

Technology and quality demands in PCB manufacture are constantly on the rise. Registration accuracy requirements when assembling and exposing PCBs are growing, combined with an increased level of productivity. The axially stiff Loewe GK coupling is used in combined pivoting/lifting units for the pick-and-place assembly process and in the Z-axes of PCB exposure systems.

Encapsulation of chips and wire bonds

Chips, wire bonds or other components on printed circuit boards are usually completely or partially covered from mechanical influences or environmental conditions.

This process is called encapsulation. Different cover sizes and formats can be processed flexibly and at a high cycle rate in systems and assembled on the PCB. The covers are removed by vacuum-assisted pick-and-place grippers on automatically convertible fixtures and placed with high positioning accuracy on the components to be encapsulated. In these highly dynamic and precise assembly tasks, the Spinplus in the XY axis with a drive system consisting of servo motor and ball screw show their strength with their precision and mass inertia-optimised design.

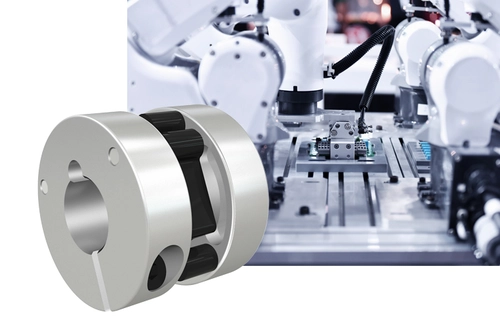

Assembly machines, cobots, rotary transfer machines

Automatic assembly machines

Assembly machines are indispensable in the rational mass production of tiny parts. Typical assembly applications are, for example, components for mobile phones, micro switches, central locking systems and controllers. Due to the extremely high productivity of these systems, absolute precision of the drive system is required. Servoflex couplings are used both when conveying the components to the various processing stations - a process requiring the utmost accuracy - as well as when placing and assembling them in the respective stations.

Portal robots and rotary transfer machines

The Servoflex couplings are used as intermediate shaft couplings in gantry and portal robots and ensure excellent synchronization in these multi-axis systems.

The pivotal criterion for collaborative robots in handling and automation applications is speed combined with precision. With compact formats, high power density and extremely low rotational inertia, BLDC motors gain points in the drive of these cobots. These motors enable the required highly dynamic work processes with permanent acceleration, deceleration and changes of direction. The inertia-optimised Spinplus coupling with its compact dimensions and high power density is a perfect partner in this case.

The lightweight aluminium Semiflex Dynamic range is used in the clocked feeding processes of rotary transfer machines. With its low rotational inertia, it promotes these accurate, highly dynamic work processes.

Vacuum gripping systems, control and measurement

Material feeding systems

Vacuum gripping systems play a major role in material feeding systems. As a result of their operating principle, they can reliably pick up even the most sensitive products in the most varied formats and sizes and deliver them to further processing stations. This is usually done through robotic or linear systems. Leveraging its high precision and low rotational inertia, the backlash-free Servoflex coupling can indeed properly support the dynamic, high-precision positioning process when products are picked up and conveyed through grippers.

Monitoring the workflow in handling systems

In most handling and automation technology processes, precise workflows are monitored by sensors and rotary encoders. The Controlflex encoder coupling ensures the exact and precise recording and transmission of measuring pulses.

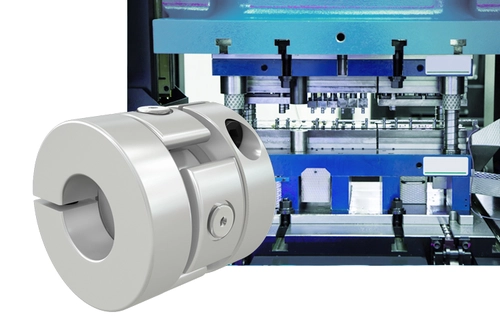

High thrust forces in servo presses, dynamic feeding in automatic wire bending machines

Precise assembly and joining by means of modern servo presses

Nowadays, automated assembly and joining work would be unthinkable without servo presses. Tasks such as precise pressing, joining, compressing and fastening of components are the specialty of these electrically driven presses which operate with a high number of cycles. Axially rigid linear coupling Loewe GK Linear enables the precise transmission of thrust forces and, thanks to its high radial and angular displacement capacity, also relieves the system from disruptive lateral forces.

Highly productive bending process in the manufacture of wire conveyor belts

Wire conveyor belts consist of a grid of differently arranged metal wires. They are used to convey a wide variety of goods in demanding operating environments, in which, for example, plastic conveyors cannot be used due to thermal conditions or the agents that may be developed. In order to be able to customise these systems in such a way that they can meet the respective requirements during production - such as load, use in liquid agents or similar - flexibly convertible automatic bending machines ensure the highly productive output of these conveyor belts in linear feeding.

The Loewe GK Linear coupling promotes the precise transmission of the thrust forces generated by the electric cylinders used in these dynamic drive systems, which operate with frequent load and direction changes in the shortest possible time. Any additional radial and angular displacements occurring are also successfully compensated for by the coupling system.