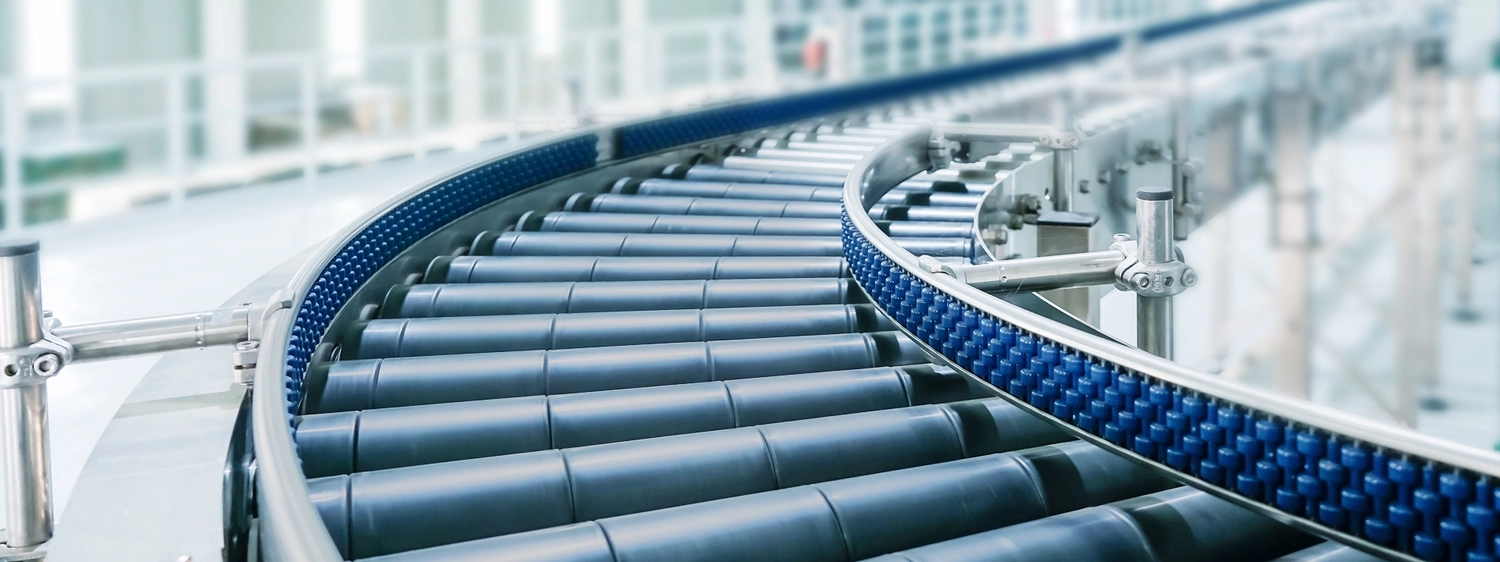

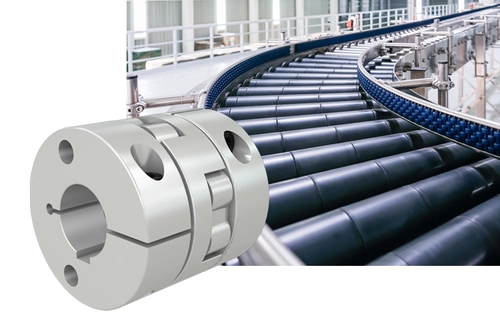

Space-saving for compact roller conveyors

Roller conveyors are mostly required to carry lightweight, small-sized items. Items are conveyed on conveyor rollers arranged transversely to the conveying direction. Driven systems are used when an item to be conveyed is to be stopped and carried further at a later point in time. For this reason, these conveyor systems often run at varying conveying speeds or in fixed-cycle operation. The conveyor rollers are driven by servo-motors in conjunction with series Semiflex couplings. In order to obtain complete conveyor systems, single modules are combined and connected in a modular system. Small-sized couplings are often used as radially mountable couplings with split clamping hubs. As a result of the high displacement capacity of precision couplings, the conveying level of each sub-module can be adjusted.

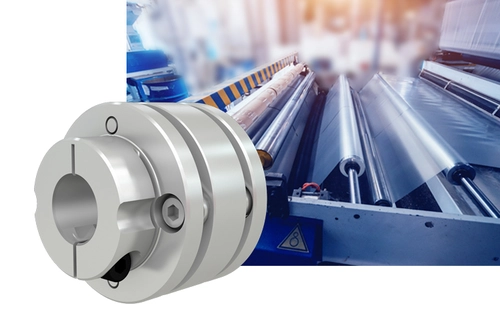

Synchronising single segments in belt conveyors

Belt conveyors are used to continuously convey items such as packages, workpieces or containers. Conveyor belts move on support rollers as circulating belts. In addition, by selecting belt coverings and the corresponding coefficients of friction, inclines can be overcome without the conveyed items slipping.

The complete system is divided into several segments with different applications, lengths and speeds; redirecting stations allow the items being conveyed to be carried in curves. Due to their precision, couplings from the Semiflex range ensure synchronisation and matching of the single segments. The compact design of the coupling promotes the compactness of the entire conveyor system.