Filigree, precise, noble or fast – all attributes that compensating couplings in the medical and pharmaceutical industries need to fulfil for medical technology products to be properly manufactured, patients to be safely and easily diagnosed or samples to be looked into accurately.

High displacement compensation and ATEX compliance in processing systems

Noble and conductive

rocess systems are used in medical technology and pharmaceutical production to manufacture drugs and medicines, among other things. Due to contact with products and the generated dust, stainless steel and ATEX-compliant compensating couplings are required.

The Loewe GK Torque can be fitted into multi-chamber process systems in tight installation conditions and can compensate for the high radial and angular displacements occurring due to the process. The Loewe GK is seamlessly made of stainless steel and also has electrically conductive high-performance plain bearings.

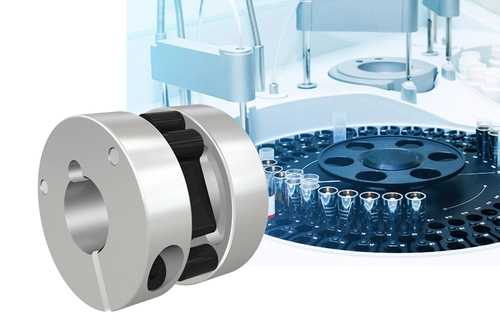

Gentle and precise in laboratory centrifuges

At high speed for analyses

The liquid component of blood, serum or plasma, is required for many laboratory analyses. In order to separate liquid from solid components, samples are centrifuged in high-speed laboratory centrifuges after withdrawal. Since this process occurs at high speed, it is essential for the entire system to run very smoothly so that the components in the samples are neatly separated without any damage. The Controlflex runs extremely smoothly even at speeds of up to 25,000 min-1 thanks to its balanced clamping hubs, and works precisely as well as absolutely synchronously with angles while protecting bearings, even with high displacement.

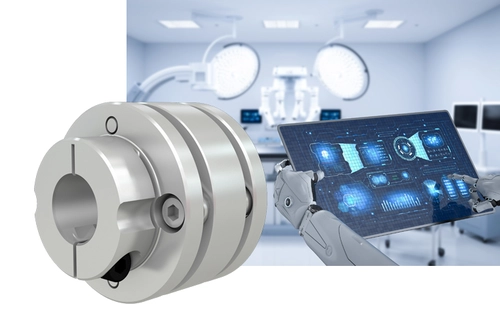

Precision and compactness in lifting devices for medical technology

Safe and gentle for diagnoses

Lifting plays a major role in medical technology applications, for example, when raising and lowering patient tables, in computer and magnetic resonance tomographs, in laboratory and analysis equipment or in various other X-ray devices. High demands are placed on these lifting systems in terms of safety, accuracy, low noise and, due to their compact design, also in terms of compactness.

As a shaft coupling in the servo-axes of lifting systems for medical technology , the Servoflex coupling makes the most of the precise movement sequence in the system thanks to zero backlash and its torsional stiffness.